Flange Segment Ball Valve

Size Range:

DN 25~250mm NPS 1”-10” (Wafer)

DN 25~500mm NPS 1”-20” (Flange)

Press. Rate:PN 10/16/25/40/63

ANSI 150/300/600

Temp. Range:

Metal Seat -29...+450℃

Resilient Seat -29...+150℃

Seal Tightness:

Metal Seat Class IV

Resilient Seat Class VI

Product Description

Product Description

V Port ball valve is also called Segmented ball valve which has the ball V notch type designed and realizes body sealing in V type,very precise and sharp in flow control and shut off medium. It is very good choice for medium like fiber slurry or solid particles.

Soft Seat: RPTFE,PEEK, PPL,Nylon,Molon,Devlon,PCTFE,etc

Metal Seat: Hard Metal like STL6 or TC, etc

Features: quite often design is wafer or flange ends, V port sealing for flow control, sharp V ball structure is precise in flow cut off, sealing could be metal or soft, the valve is in compact design saves cost.

HRSO ball valves:

Materials: carbon steel, alloy steel, stainless steel, duplex steel,bronze, Inconel,Hastelloy,Monel, Incoloy etc.

Carbon Steel A105N,F11,F22,F5,F9 or WCB,WCC, WC6,WC9,C5, C12 etc.

Low Carbon Steel LF2 or LCB,LCC etc.

Stainless Steel F304,F316, F316L,F347 or CF8, CF8M, CF3M,CF8C etc.

Duplex Steel such as F51,F53, F55 or 4A,5A,6A, CD3MN, CD2MWCuN, CN7M (Alloy 20) etc.

Bronze C95800, RG5 etc.

Other special materials like Inconel 625 could be supplied by request.

Application Standard:

Design: API6D ,ASME B16.34 ,BS5351,ISO14313

Fire safe:API607,API 6FA,

Face-to-face: API 6D/ ASME B16.10

Flanged Ends:ASME B16.5/B16.47 /MSS SP-44/DIN/EN1092-1/GOST33259/JIS

BW Ends:ASME B16.25

Inspection Test :API 598,API6D,ISO5208,EN12266-1

Temperature Ratings :ASME B16.34

Certificate:EN 10204 type 3.1

Markings: MSS SP25

Tags: V port ball valve, V port control valve, Segment ball valve, Jacket Segment ball valve, V port control ball valve.

Features:

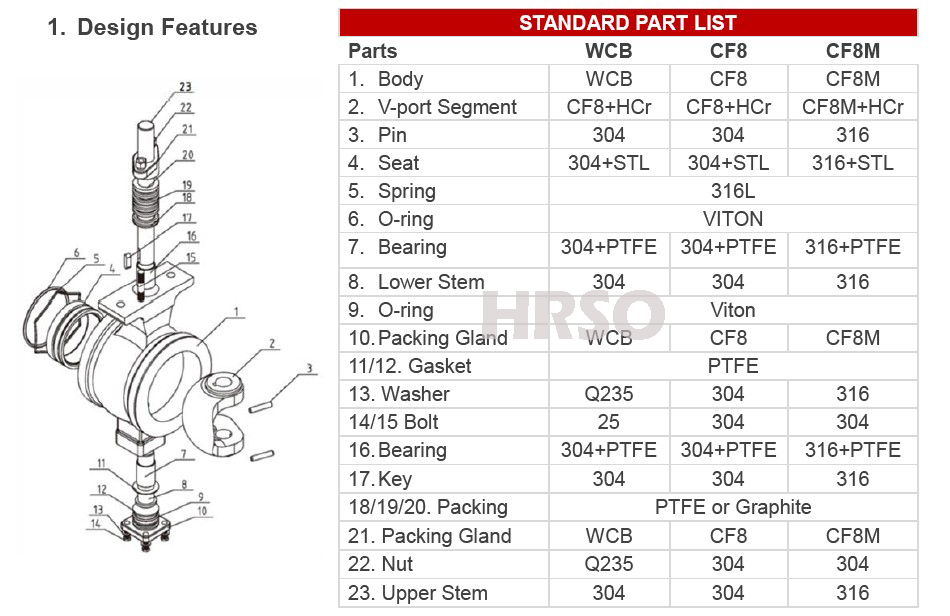

1. Body:

a) Integral body design offers greater rigidity against fluctuating pipe loads.

b) Eliminates the leak path associated with two piece body designs.

c) Both wafer and flange connection are available.

2. Core:

a) Specially designed V-notch ball provides strong cutting stress and tight sealing.

b) Hard chromium, nitriding, and HCOF treatments are all available for the ball surface treatment, improving hardness,

abrasion resistance, fatigue resistance, corrosion resistance and performance under high temperature.

c) Well ground notched ball surface ensures small operating torque and tight seal, especially for metal seated

segment valve.

3. Seat:

a) For valve rated under class 150, retainer is casted on valve body to eliminate any possible space between seat

ring and body for residue accumulation. Consequently, this ensures perfect seal。

b) Specialized spring design decreases valve torque while providing force for tight sealing.

c) Pressure energized seat design offers excellent sealing even at very low differential pressures.

4. Stem:

a) The stem is finely ground to match the actuator excellently, which prevents rocking motion and potential failure

of the segmented valve.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kyle Yu

Phone: 0086-13588930107

E-mail: sales@hrsovalve.com

Whatsapp:0086-13588930107

Add: Yang'er Road,Oubei,Wenzhou,Zhejiang,China