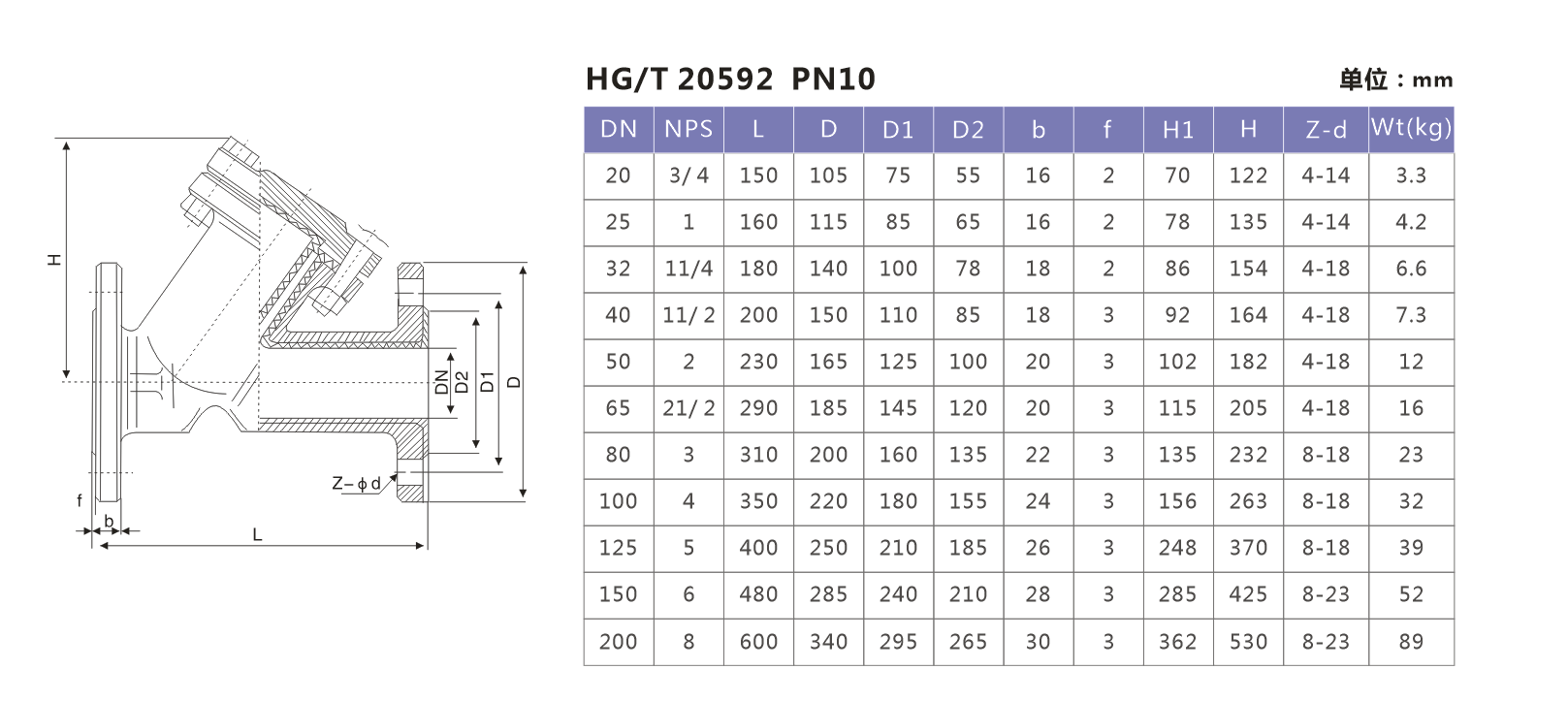

PTFE Lined Y type Strainer

DN25-DN200

PTFE Lined

Body Material: Carbon Steel

ASTM A216 WCB

Filter /Strainer principle:

The water to be treated by the filter enters the body from the water inlet, and the impurities in the water are deposited on the stainless steel filter screen, thereby generating a pressure difference. The pressure difference between the inlet and outlet is monitored by the differential pressure switch. When the pressure difference reaches the set value, the electric controller sends a signal to the hydraulic control valve and the drive motor, which triggers the following actions: the motor drives the brush to rotate, cleans the filter element, and opens the control valve at the same time. For sewage discharge, the entire cleaning process only lasts for tens of seconds. When the cleaning is over, the control valve is closed, the motor stops rotating, the system returns to its initial state, and the next filtration process begins. After the equipment is installed, the technicians will debug, set the filtration time and cleaning conversion time, the water to be treated enters the body from the water inlet, and the filter starts to work normally. When the preset cleaning time is reached, the electric controller will supply the hydraulic control valve. , Drive the motor signal to trigger the following actions: the motor drives the brush to rotate, cleans the filter element, and at the same time the control valve is opened to discharge the sewage. The entire cleaning process only lasts for tens of seconds. The system returns to its original state and begins to enter the next filtering process. The inside of the filter shell is mainly composed of coarse filter screen, fine filter screen, suction pipe, stainless steel brush or stainless steel suction nozzle, sealing ring, anti-corrosion coating, rotating shaft, etc.

Classification by filtering principle:

1. Self-cleaning filter:

Self-cleaning filter is a kind of filter that directly intercepts impurities in water, removes suspended solids and particulate matter in water body, reduces turbidity, purifies water quality, reduces system fouling, algae, rust, etc., so as to purify water quality and protect other equipment in the system from normal. Precision equipment for work.

Main components of self-cleaning filter:

Motor, electric control box, control pipeline, main pipe assembly, filter element assembly, 316L stainless steel brush, frame assembly, drive shaft, inlet and outlet connection flanges, etc. The self-cleaning filter overcomes many shortcomings of traditional filtration products, such as small dirt holding capacity, easy to be blocked by dirt, the filter part needs to be disassembled and cleaned, and the filter status cannot be monitored. It has the function of filtering raw water and automatically cleaning the filter element. The self-cleaning filter provides uninterrupted water supply to the system when it cleans and discharges sewage, and can monitor the working state of the filter, with a high degree of automation. It covers the needs of various filtration precisions from 10um to 3000um. The self-cleaning filter adopts the advanced technology of international water treatment industry equipment, and can be installed vertically, horizontally, or upside down in any direction and in any position. It can be used in industry, agriculture, municipal power, electronics, medicine, food, printing and dyeing, construction, steel, metallurgy, Water filtration in various industries such as papermaking.

2. Fully automatic filter:

The automatic filter is a set of equipment widely used in the filtration industry at present. It overcomes many shortcomings of traditional filtration products, such as small dirt holding capacity, easy to be blocked by dirt, the filtration part needs to be disassembled and cleaned, and the filter status cannot be monitored. Filter and automatically clean and drain the filter element.

The automatic filter is composed of shell, multi-element filter element, backwash mechanism, electric control box, reducer, electric valve and differential pressure controller. The diaphragm in the shell divides its inner cavity into upper and lower cavities. The upper cavity is equipped with multiple filter elements, which makes full use of the filter space and significantly reduces the volume of the filter. The lower cavity is equipped with a backwash suction cup.

Please contact sales@hrsovalve.com for more information.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kyle Yu

Phone: 0086-13588930107

E-mail: sales@hrsovalve.com

Whatsapp:0086-13588930107

Add: Yang'er Road,Oubei,Wenzhou,Zhejiang,China