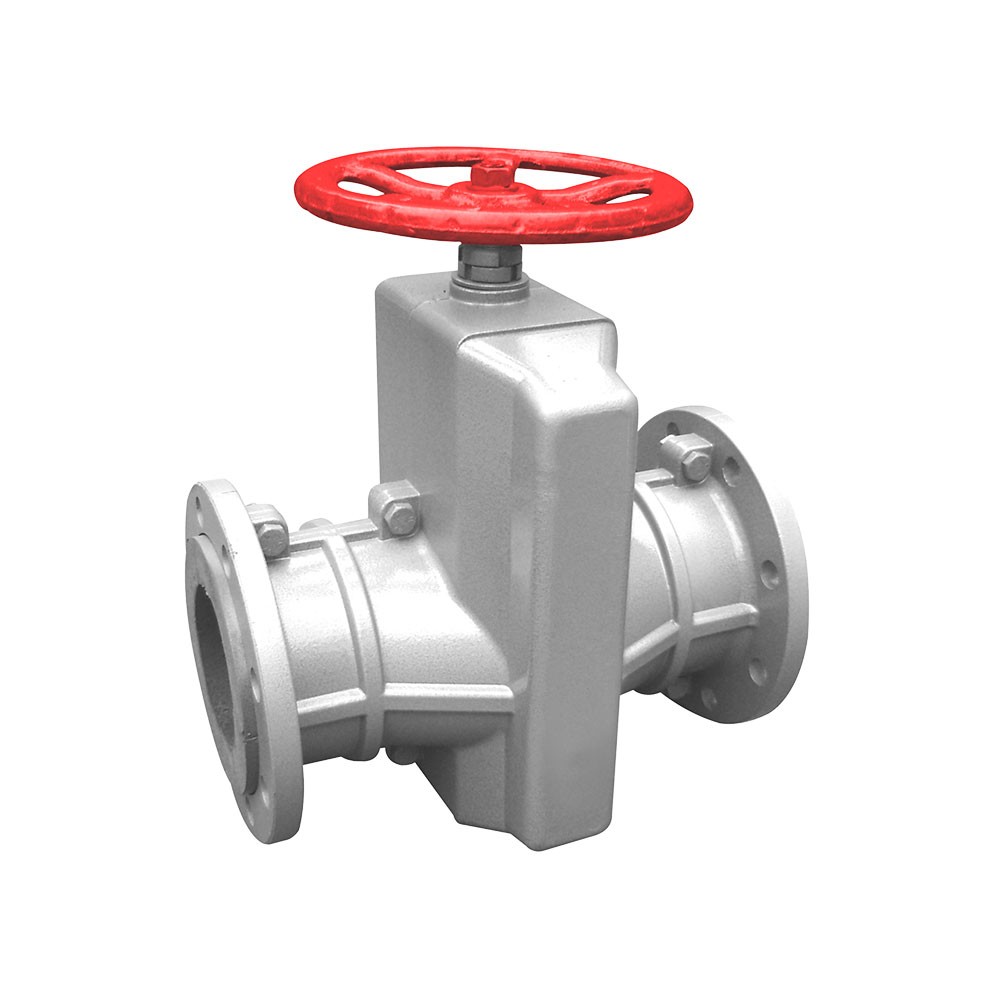

Aluminum alloy pinch valve

Aluminum alloy pinch valve

DN25-DN300

Model:GJ41X-10L

Aluminum alloy pinch valve, also known as aluminum alloy pinch valve, aluminum alloy hose valve, consists of left and right aluminum alloy valve bodies, rubber tube sleeves, large and small valve stems, upper and lower gates, guide posts and other parts. Wear-resistant, anti-corrosion, anti-freezing, good sealing performance, just need to replace the rubber sleeve, it is as good as new, the valve body can be used permanently, and the service life is 4-6 times that of ordinary valves. The driving methods include manual, pneumatic, electric and other methods, and non-standard products can also be customized according to customer needs.

Product features: wear-resistant, anti-corrosion, anti-freeze, good sealing performance, just need to replace the rubber sleeve, it is as good as new, the valve body can be used permanently, and the life is 4-6 times that of ordinary valves.

Working principle of aluminum alloy pipe pinch valve

When the handwheel is turned in the same direction, the large and small valve rods drive the upper and lower gates at the same time, compress the tube sleeve, and close, and then reverse to open, so that the gate reciprocates up and down between the guide posts to complete the valve opening and closing work. In addition, due to the bearing capacity of the rubber sleeve, when switching, if the operator feels a moderate amount of resistance when rotating the handwheel, it has reached the opening and closing extreme.

Main technical parameters of aluminum alloy pinch valve

1. Scope of application: chemical industry, petroleum, power generation, alkali plant, mineral processing, cement, coal preparation, non-metallic and other industries, can quickly control the pipeline concentration sand flow and cut-off.

2. Use medium: pulp, sewage, slag, cinder, sediment, etc.

3. Applicable temperature: -30-85, higher temperature can be customized separately.

4. Nominal pressure: -0.3-2.5Mpa (ordering instructions).

5. Flange implementation standard: (JB/80-91). or as per your standard, please specify .

Main outline and connection dimensions of aluminum alloy pinch valve

| DN | L | B | H | Do | Dn | D | D1 | d | Z | F | End Type |

25 | 99 | 14 | 126 | 100 | 25 | 100 | 78 | 11 | 4 | 2.5 | Flange |

32 | 125 | 14 | 144 | 100 | 30 | 120 | 90 | 12.5 | 4 | 2.5 | Flange |

40 | 146 | 16 | 165 | 125 | 38 | 130 | 100 | 13.5 | 4 | 2.5 | Flange |

50 | 190 | 18 | 190 | 165 | 50 | 160 | 125 | 18 | 4 | 3 | Flange |

65 | 235 | 18 | 200 | 190 | 65 | 180 | 145 | 18 | 4 | 3 | Flange |

80 | 290 | 20 | 207 | 200 | 80 | 195 | 160 | 18 | 4 | 3 | Flange |

100 | 370 | 20 | 228 | 250 | 96 | 215 | 180 | 18 | 8 | 5 | Flange |

125 | 445 | 22 | 260 | 520 | 120 | 245 | 210 | 18 | 8 | 5 | Flange |

150 | 490 | 24 | 340 | 320 | 145 | 280 | 240 | 20 | 8 | 5 | Flange |

200 | 550 | 24 | 429 | 400 | 195 | 335 | 295 | 20 | 12 | 5 | Flange |

250 | 620 | 26 | 512 | 400 | 245 | 405 | 335 | 22 | 12 | 7.5 | Flange |

300 | 810 | 28 | 595 | 500 | 295 | 460 | 410 | 22 | 12 | 7.5 | Flange |

If you need any more information, please contact sales@hrsovalve.com

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kyle Yu

Phone: 0086-13588930107

E-mail: sales@hrsovalve.com

Whatsapp:0086-13588930107

Add: Yang'er Road,Oubei,Wenzhou,Zhejiang,China